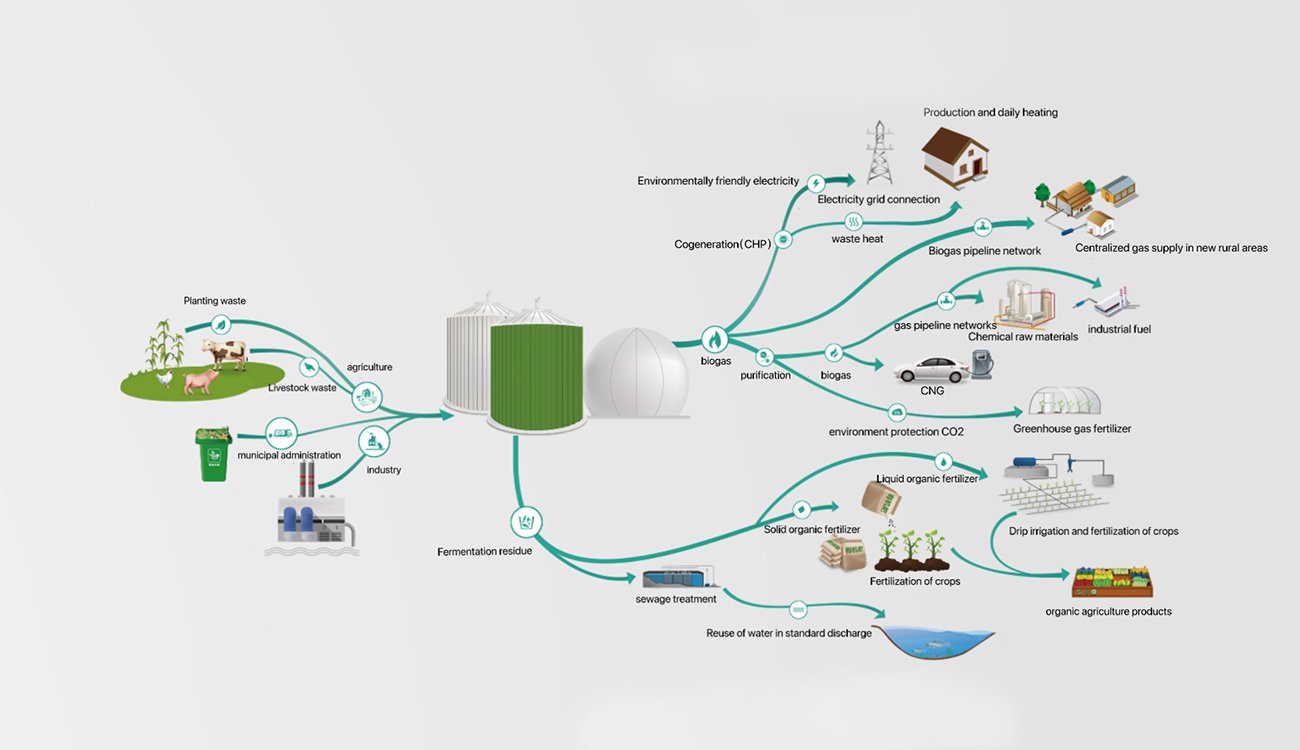

The technological process of a biogas project generally includes such links as raw material collection, pretreatment, anaerobic fermentation, biogas collection and purification, and biogas residue and slurry treatment, which are specified as follows:

Raw Material Collection: Collect fermentable organic wastes, such as livestock and poultry manure, crop straw, vegetable wastes, and urban organic garbage. Different raw materials are collected in different ways. For example, pig farms can collect manure by means of automatic flushing, manure scraper removal, or manual transportation, and the concentration of raw materials collected by different methods varies.

Raw Material Pretreatment: The collected raw materials are crushed and sieved to remove impurities, such as long grass in cow and pig manure, chicken feathers, shell powder, and gravel in chicken manure, so as to prevent pipeline blockage during the fermentation process. At the same time, adjust the moisture and pH value of the raw materials. Generally, the moisture content is controlled between 60% and 80%, and the pH value is adjusted to about 6.5-8.0. In addition, the stability of fermentation and gas production can be improved by mixing different types of raw materials.

Anaerobic Fermentation: The pretreated raw materials are sent to an anaerobic digester (biogas digester) for fermentation by anaerobic microorganisms under strictly anaerobic conditions. The fermentation process includes four stages: hydrolysis, acidification, acetylation, and methanation. The temperature is generally controlled at 35-55℃. During this period, it is necessary to maintain an appropriate pH value and stirring frequency to promote the metabolic activities of microorganisms and increase biogas production.

Biogas Collection and Purification: The biogas generated during the fermentation process continuously accumulates at the top of the digester. The biogas is pumped out of the digester through pipelines and air pumps, and preliminary slag removal is carried out. Then, impurit.

If you have any needs or questions about environmental protection, please leave a message below and we will provide you with the most suitable systematic environmental protection solution as soon as possible.